What is the best way to cool a building? In this comparison between four different options, we look at energy efficiency, installation complexity, noise and possibilities created by the placement of the cooling unit.

Click the images for a large version.

Comfort ventilation with cooled supply air

1: Unit with integrated EcoCooler

We recommend comfort ventilation with EcoCooler integrated in the air handling unit. The premises can be free-cooled by means of the outdoor air for much of the year. When this is insufficient, EcoCooler starts and cooled supply air is obtained in the most energy-efficient way. The unit has an EER of up to 7.

In many buildings, the air flow varies considerably and a highly accurate supply air temperature is required. EcoCooler can be used in combination with VAV systems, as the cooling power can be adjusted steplessly. EcoCooler is used in combination with active devices if individual control is required in every room.

A simplified installation approach means no more coolant coolers on the roof, and less complex cooling systems.

2: Traditional installation

In a traditional installation, the ventilation unit cools the supply air using cold water from the liquid cooling unit on the roof.

Installations with liquid cooling units require more demanding maintenance than installations with integrated cooling units. External liquid cooling units frequently cause disruptive noise problems.

Traditional installations take up a lot of roof space that could be used instead to create interesting commercial areas. Roof terraces, gardens, pools – the possibilities are endless when the cooling unit is integrated into the air handling units instead of being placed on the roofs.

As regards energy efficiency, the traditional installation is less effective than an installation with EcoCooler.

Comfort ventilation with cooling baffles or fan convectors/fan coils

3: Unit with integrated EcoCooler

To create the most energy-efficient solution, we recommend cooling the supply air with EcoCooler, which is integrated in the air handling unit. The new EcoCooler can give an EER of up to 7.

If cooling the space with baffles or fan convectors/fan coils is desirable, a separate liquid cooling unit can be used to achieve this. In this case, the water for the baffles then only needs to be cooled to 14°C by the liquid cooling unit, which promotes energy efficiency.

This makes the entire system solution more energy-efficient than the traditional installation with cooling baffles and fan convectors/fan coils.

This installation is also simpler and more cost-effective. The liquid cooling unit on the roof may also be considerably smaller.

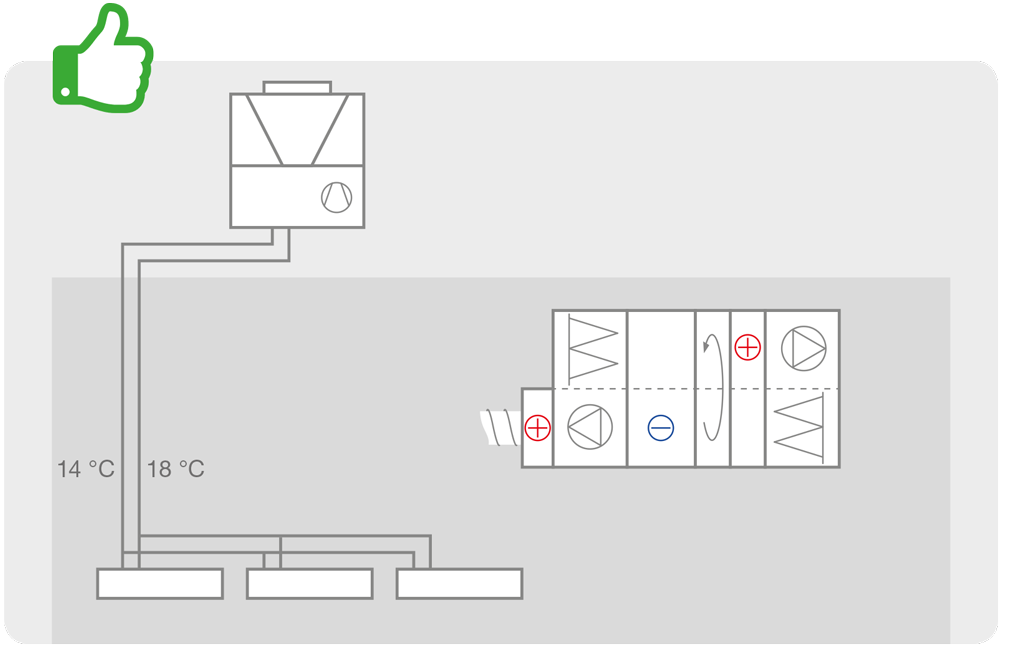

4: Traditional installation with cooling baffles

In a traditional installation, the ventilation unit cools the supply air using cold water from the liquid cooling unit on the roof. The internal loads in the rooms are cooled using baffles or fan convectors/fan coils.

The water for the cooling coil in the ventilation unit usually needs to be at 7°C in order to dehumidify the outdoor air.

For cooling baffles and fan convectors/fan coils, the supply water needs to be warmer to prevent condensation. The liquid cooling unit on the roof produces water at 7°C that then has to be shunted to 14°C.

Producing water at 7°C and then shunting it to 14°C is not energy-efficient, and the EER for the liquid cooling unit drops.

Learn more about: EcoCooler – integrated cooling unit

Others also read

What to consider when designing cooling in AHUs

What to consider when designing cooling

...The most profitable sustainability investment

When it comes to energy efficiency, discussions often lead to replacing windows, replacing lights or additional ...

Replacing AHUs: Calculate energy savings and payba...

An older ventilation unit that appears to be in good condition may be unexpectedly profitable to replace. It is ...

The advantages of using IV Produkt Cloud

View examples of how IV Produkt Cloud simplifies service, support and commissioning of our air handling units