Why calculate LCC – life-cycle cost?

When LED lamps entered the market at €7 each, many people wondered why they should replace their incandescent bulbs, which only cost a Euro. So, why has the LED lamp completely taken over today while the manufacturing of incandescent bulbs has ceased?

With total costs and environmental impact in mind

Every day, municipalities, regional authorities, businesses and others procure enormous amounts of products that use energy. Historically, procurement processes have focused on obtaining the lowest possible purchase price in the belief that this represents the best investment. With time, the mindset has altered and it has become increasingly common to look at the life-cycle cost (LCC) of a product when deciding which products to buy.

Making a decision based on LCC is smarter than prioritising a low purchase price, in terms of both finances and environmental impact. A product that consumes energy, an air handling unit for example, costs money to operate. And it has a long service life, often in excess of 20 years. A unit that consumes less energy will cost significantly less to run. This is part of the model used to calculate a product’s life-cycle cost.

In addition to operating costs, the cost of servicing, maintenance, spare parts, environmental impact and even the decommissioning of the product need to be taken into account. These costs can account for as much as 90 % of the lifetime cost. Another bonus effect of buying a more energy efficient product is that it increases property value.

How to make an LCC calculation for an air handling unit

There are different models for calculating a product's life-cycle cost depending on which product or industry you are dealing with. When it comes to air handling units, we use the LCCE model, where we calculate the investment and energy cost.

LCC =

Investment + Total energy cost

In the example below you can see how an air handling unit with a higher procurement cost can still be the most cost-effective option, seen over a usage time of 20 years. In addition, Air handling unit 1 may have a lower maintenance and environmental cost, which further strengthens the LCC calculation.

| Air handling unit 1 | Air handling unit 2 | |

|---|---|---|

| Investment | €19,000 | €16,500 |

| Total energy cost* | €28,500 | €48,700 |

| Life-cycle cost | €47,500 | €65,200 |

*The calculation is based on half-day operation. For full day operation the energy cost would have been higher and the difference in life-cycle cost even greater.

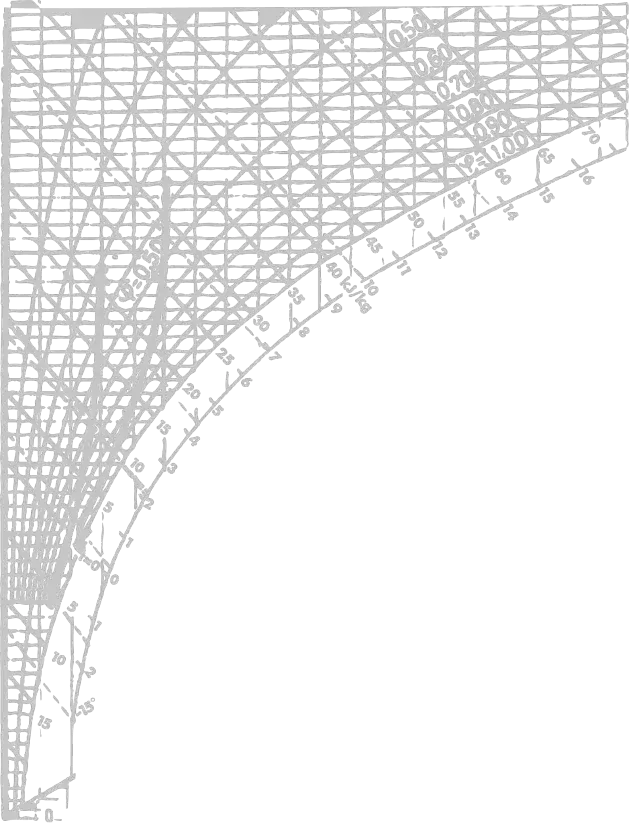

LCC in IV Produkt Designer

In our product selection program IV Produkt Designer, you can easily calculate the life-cycle cost of energy (LCCE) for an air handling unit, thus finding the best investment.

The calculation takes into account the investment cost and energy cost, but you can also add manual entries, such as maintenance.

Air handling with focus on LCC

Focus on life-cycle cost is very close to our heart. Considering how much an LCC calculation affects the total cost of an air handling unit and its environmental impact, we believe having this focus is self-evident.

Ongoing projects?

Together, let's find the optimal solution for you!