There are some old key indicators for calculating temperature and relative humidity that are used out of habit, such as a lower temperature but high humidity. Taking climate change into account, it is a good idea when designing cooling capacity to consider the current climate conditions where the unit will be installed.

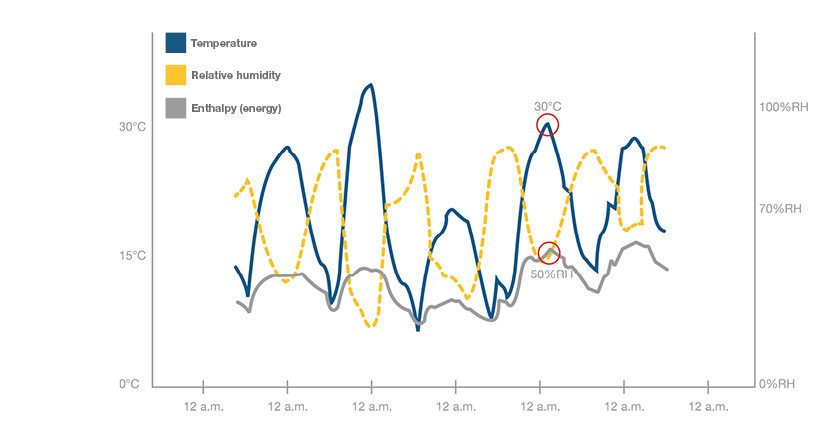

When calculating cooling, many people base their calculations on the highest measured temperature at a certain time and highest measured relative humidity at another point in time. These two maximum values do not typically occur at the same time. This results in an oversized air handling unit that is more expensive to buy, is costlier to run, harder to control and less efficient. It’s like buying a big bus when you just need a car.

How can temperature and relative humidity be used to calculate an appropriate size for the air handling unit?

Here is an example:

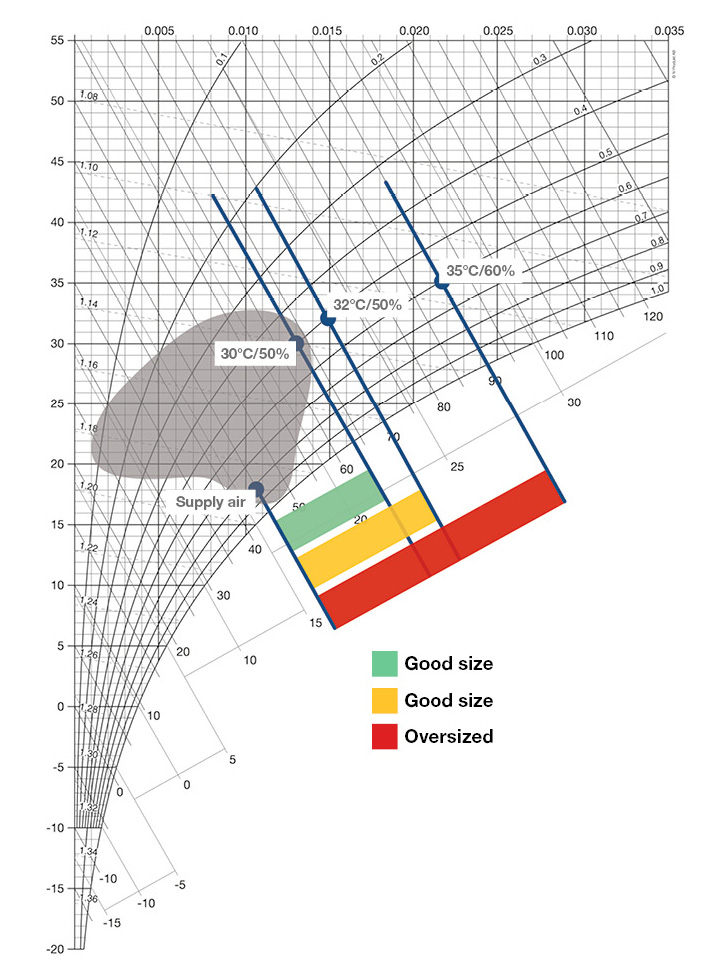

When you choose 30°C/50%, which refers to a total energy (enthalpy) of 64.1 kJ/kg, you get an output level that can handle almost all of the year’s operating modes. On the occasions during the year when the temperature is higher than calculated for, the total energy is usually lower than at the calculated time.

Comparison between different capacities

The grey area represents the most common temperatures and relative humidity over a summer.

The diagram shows three different output levels that are compared to each other to indicate how much energy is required to reach a supply air temperature of 18°C for the different values.

35°C/60% falls far outside the grey area, indicating that this state rarely occurs. This means that it is unnecessary to have overly high cooling capacity because the unit becomes too large and costly. 30°C/50% is sufficient to cover the cooling needs on most days. Although there will be a few days that fall outside the cooling capacity, the unit will still deliver a good power while maintaining good control functionality throughout the cooling season.

At 30°C/50% or 32°C/50%, the cooling capacity is appropriately sized in this case and still has good capacity for the hottest days. This results in an air handling unit that is energy efficient, cost-effective and reliable with good control functionality

Note: While air handling units with integrated cooling in warmer climates are sized to deal with higher temperatures, they still adhere to the same principle as above.

Summary

- When reading maximum temperature and relative humidity, read the data for the same day

- Consider whether the key indicators you use need to be updated

- Air handling units with integrated cooling that has the correct cooling capacity are energy efficient, cost-effective, reliable and have good control functionality

Others also read

The most profitable sustainability investment

When it comes to energy efficiency, discussions often lead to replacing windows, replacing lights or additional ...

Intervent talk AHU news at the Nordbygg tradeshow...

Join Ville from Intervent – our Finnish representative – as he guides us through our latest innovations...

Calculate energy savings and payback before replac...

An older ventilation unit that appears to be in good condition may be unexpectedly profitable to replace. It is ...

The advantages of using IV Produkt Cloud

View examples of how IV Produkt Cloud simplifies service, support and commissioning of our air handling units